In

the 1960’s, Queensland Railways had four drawgear classifications on their

rollingstock fleet. Auto (D1), Premium (D2) hooks on the steel rollingstock

built in the 60’s, Select (D3) hooks on steel wagons built in the 50’s and

newer wooden wagons, and ordinary (D4) hooks on the older wagons and all four

wheeled wagons. By the early 1990’s it was all auto (D 1) couplings and the buffers

were gone. The era I model had all classes including transition coupling to

couple hooks with auto couplings.

At

first on my wagon fleet I tried to have different class/standards of couplings as

the prototype, the method in my madness was to marshal trains as per QR instructions.

Stronger drawgear to the front and not so strong on the rear, maybe have the

same end results as the prototype if the instructions were not followed.

I

was not over concerned if the couplings did not centre, the prototype do not

centre, it’s up to the Shunter to line up the couplings. Most did not have

grease on the slide plate and often required two hands a lot of grunt. The

height also varied considerably, loaded wagons with empty wagons, new wheels

with last turning could alter the height quite a bit. Provided the jaw hit the knuckle

tongue on the other coupling and the coupling locked, all was good. 1620 DEL’s

were noted for their low coupling, often you would stop short and close one jaw.

Some times it was a two man job, one shunter would lift the coupling and the

other would slide a dog spike under the stem. The good book suggests after coupling auto

coupling they should be tested by stretching them, the locking block in bottom pin couplers often did

not drop.

All

was good on the layout until I started making up operations sessions requiring

a number of shunting moves. In big strings of wagons the # 711 did not like being

pulled and pushed about and would let go. Often in hard to reach locations,

plus it added extra time into the shunt. Maybe I had given them a flogging over

the years. Yes, the method in my madness was working to good. The scale whisker

coupling have been out for some time and are great, they are better than sliced

bread. I use the # 153 short centerset on wagons without buffer. # 158 medium

centerset subject to buffer size and # 156 long centerset for bigger buffers. In

each application, I use the shortest shank coupling for the job. When pushing

back, the long shank couplings swing to one side and on curves could cause

wagons to derail. I have been using them on all my new rollingstock and they

work great and look awesome. I have found them easy to fit. Over the last few

years I have change my fixing methods a bit. On open wagons without a load and platform

wagons I make the coupling box as part of the floor.

At

first I was using styrene for all of the compounds including the coupler pivot.

Thinking that this may wear over time the next lot of wagons I included a brass

bush made from 1/8” brass tube. The last lot I made I used a 1/8” brass rod (3.1

mm) in which I drilled a 1 mm hole in the centre using the lathe. The rod was

cut down to the same thickness as the coupler shaft. A 1 mm brass rod was used

to mount the pivot block. This was done on the PCUY wagons which you can find

on the blog. http://westgateswr.blogspot.com/2019/01/pcuy-wagons.html

Recently

I made some grain wagons, the wagons were fitted with traps and the floor was

not visible. I fixed the couplings with a self-tapping screw, much the same size

as the coupling pivot hole. A washer was added to provide extra support for the

bottom of the coupling. Check the size, it may foul the wheels if to close. With

styrene made wagons the self-tapping screws can form a bubble around the fixing

hole, this will need to be removed with a file. The mounting hole can be some

what large also.

This

coupling is to far out from the headstock, I was using the fixing point from a

previous coupling.

711 Coupling

Using a 2 mm screw

All

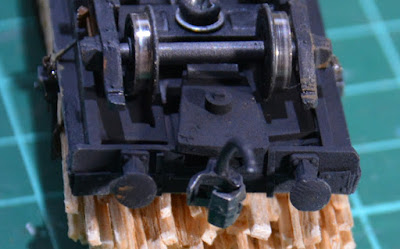

my four wheeled hopper wagons are Peco TT underframes, these were available in

the seventies. At first I ran them in blocks of five using dummy knuckles. A

small Kadee rounded box was used at the end of each block, this didn’t look all

that great and did not work all that good. Moving into operations I wanted to

be able to change the orders for each day, to do this working couplings were

required on all wagons. After some thinking, a channel was cut into the

headstock with a dermal cutter to take the coupling shank. Short shank

couplings # 153 was used with a brass plate top and bottom to hold the

underframe together and to mount the coupling. Fixing the coupling was the same

as above with the 2 mm screw and a bass 1/8” bush. Yes, a little bit of a compromise, once painted they don’t look to bad and they fit the

bill until something better comes along.

The

QR coupler height is 2’ 8 “(9.3 mm for the modeller), for mounting I use the casting

mould line in the centre of the knuckle for this measurement. I made a coupler

gauge to ensure all wagons have the same height coupling. The coupler release pin

is raised a little to ensure it don’t catch on points. So buffer do not buffer

lock on curves and points I try to mount the back of the coupler pocket in line

with the front of the buffer. I use Peco track and standard points with a 24

inch radius on the turn out. The curve points have an 18 inch radius turnout.

Placement of the coupler should be checked if running on less than 24 inch

radius curves. This may not look prototypical with a large gap between wagons,

our models run on much small radius curves than our rail networks use and do

not have springs in the buffers. The modern era without buffer it is more achievable,

but the slack in model couplings is greater than the prototype draft box. On

the prototype, a train of 40 wagons will have equal to one wagon of slack

across the draft packs.

Trust

you find this helpful in your modelling.

A very interesting read. Good information for all

ReplyDeleteMany Thanks, your comments are much appreciated. Arthur

Deleteyour blog was very informative for all.

ReplyDeleteMany Thanks, your comments are much appreciated. Arthur

DeleteMany Thanks, your comments are much appreciated. Arthur

ReplyDeleteMany Thanks, your comments are much appreciated. Arthur

Delete