Looking back to the 1960’s, petrol “bombs” (wagons) were a common site on goods trains. A fuel depot on the layout could give me a number of shunt moves to make the layout more interesting.

Until the mid-1990’s there was a daily fuel train from Brisbane to the South West, conveying wagons for Toowoomba, Warwick, Goondiwindi, Dalby, Miles, Roma, Charleville, Quilpie and Cunnamulla.

Towards the end (2007/8), the service was reduced to three days a week and the train conveyed fuel for Miles, Roma, Charleville and Quilpie, and at times Dalby.

Empty tank wagons returned to Brisbane on Timetabled goods/freight trains with high priority.

As with August post, an Australian petroleum company was chosen, Golden Fleece. I don’t any photos and don’t recall any Golden Fleece country fuel depots. To mark the spot, a freelance depot was drawn up on paper. This would give a visual location where to place the wagons. On the prototype many fuel depots were some distance from the railway. Let’s look at some country fuel depots and unloading points to see what will fit in the space available.

The Caltex siding in

Bundaberg (Woongarra Branch) has facilities to unload a number of wagons with a

pump compound.

Piping suggest three different products arrived in tank wagons. Standard, Super and Diesel would be my guess. Avgas and kerosene in small quantiles would come in 44 gallon drums. Many depots had a drum shed that would also fill 44 gallon drums for customers. These depots served the local community in the district. Many depots had tanks that could be placed on the depot truck. The depot could supply local service stations, sheep/cattle properties, farms etc. their fuel needs. My guess is that the depot would have a weekly run to smaller towns and customers in the area. All this came to an end when the coastal terminal started supplying country areas direct by road.

If you were looking for something quick without building a full depot, pipes could be added trackside and the depot, tanks etc. could be photos on the backdrop.

The 1963 list of

Stations, Stopping Places and Isolated sidings will give some locations to look

at. Having said that, not all fuel depots had siding, and don’t give a true

picture of what tanks wagons were on trains at that location.

Dalby area.

Glenmorgan

Branch:

Shell - Dead end siding 3

chain long.

Ampol Petroleum (Qld)

Pty. Ltd - Loop 2 chain long. (1955).

This Caltex

Depot on the Glengorgan Branch in 2004 is most likely the Ampol depot, the tank

arrangements is similar to other Ampol depots.

Bell Branch:

Modil Oil Coy – Dead end

siding 2 chain long.

Beelbee Sawmilling Coy,

Pty Ltd – siding loop 10 chain also used by Caltex.

B.P. Coy’s – Dead end 3

chain long.

Phillips Oil Products Ltd

- Dead end 3 chain long.

Golden Fleece Petroleum -

Dead end 2 chain long.

John

Kerr notes show delete Esso Standard Oil Aust. Pty Ltd siding in 1988. My guess this would have been the

Phillips siding.

Miles.

Shell Coy Siding (Off Fork). (Used by Caltex also). At one stage, Shell set up a distribution depot off the main line on the Toowoomba side of town.

The B.P siding is not shown. A collection of photos taken in 2024.

Roma

318 M 36 Ch. B.P Ltd Siding – Dead end

318 M 43 Ch. Modil Oil Co’s Siding -

Dead end.

318 M 45 Ch. Shell Co’s. Siding – Dead

End.

318 M 47 Ch. Ampol Petroluem Qld Ltd.

Siding. Loop 1½ Ch.

319 M 12 Ch. Caltex Oil (Aust) Pty. Ltd and H. C. Sleigh (Qld) Pty. Ltd (Golden Fleece) 319 M Ch. Phillips Oil Products Ltd – Dead End. A note on the plan shows Phillips cross out and Esso added. The siding was added in November 1963.

Some photos of the area showing what’s

still left in 2020

The track in the foreground is the

western main line. Back in the 1960’s there were sidings for the oil company

siding, the western main line and the Injune branch.

Charleville.

The siding book 1963 shows the

following;

Murweh Town Council Siding (482 M. 64

Ch.). This was the local Power House. A few years earlier boilers were wood

fired, there was a network of tracks through the wood stacks there trolleys

could be loaded and wood taken to the boilers. In later years a tank wagon was

regularly placed in the siding beside a larger tank.

Mobil Oil Coy’s Siding (483 M. 37 Ch.)

Purr Pull Oil Coy, Siding) (83 M. 40 Ch.) Same siding as Mobil, a few years later Ampol was added to the siding.

This Golden Fleece wagon

is unloading to a fuel depot that is some distance from the railway siding, the

depot is not visible from the line. Beside the tracks is a couple of pipes. The

siding has unloading pipes for three companies. The Mobil depot is on the other

side of the street, Ampol depot is adjacent to the line on station end of the

siding. Wagons need to place next to the respective companies unloading point, I

would think there would be some sorting out to be done, one could bet their

bottom dollar they don’t arrive on the train in the correct order. Mobil came from Cannon Hill, Ampol from

Lytton, and Golden Fleece from Whinstanes.

Ampol wagon placed next to a pit for unloading, the hose have a storage pipe. The depot was just outside the railway fence adjacent.

Not shown in the book is the Shell

siding. Shell tanks were discharged in the Wool Road near the station.

Covered pit with a pipe connections to the depot which was located on the other side of the next block. The depot is not visible from this location.

OB wagon placed for unloading.

John Kerr’s notes show in 1960, Caltex Oil were using siding accommodation in the yard.

With diesel locomotives coming to the area in 1960, the fuel point at Cunnamulla for refuelling the Westlander Power Car was moved to Charleville a few years later.

A bit of a rough ride, on passing the home signal at Charleville the train came to a sudden stop as the engine couldn’t decide which track to take??. (Cocked points)

There is a refuelling point in the loco shed and one on the main line.

BP fuel depot at Charleville, a dead end siding for both tanks and drums. BP depots had much the same architecture across all their depots. Tanks on stands and brick buildings.

BP Depot. B.P Co.’s Siding. This siding ran off the Goods Shed road.

Front gate, street view.

Rail side of the depot.

Looking at the photo,

these tank wagons are Shell “OB” class wagons. The giveaway is the handrail at

the top of the ladder and a silver tank.

Each company set up was similar across the state, BP tanks were on stands, Ampol had vertical tank farms, others the tanks horizontal or length ways.

Quilpie

The siding book don’t

show any fuel sidings.

John Kerr notes show

approval was given to Shell in 1961, a departmental siding was extended 170 ft.

Caltex was also given approval. In 1964 Golden Fleece was granted a lease to

use the Esso siding.

The body of an HH (HJ) wagon being used as a drum store in the Shell Depot at Quilpie.

Looking at oil companies they all have their own distinctive features, company colours we see at service stations etc. Smaller amount of fuel and oil was moved in drums, there was a couple of sizes, and the most popular was the 44 gallon or 205 litre drums. These too were in company colours. The colour may have changed due to product.

|

Shell |

Silver |

|

Golden Fleece

|

Silver (Fuel) |

|

Golden Fleece

|

Blue/Yellow (Oil) |

|

Mobil |

Brown |

|

Castrol |

Green, some had a white

band around the centre. |

|

BP |

Green |

|

Esso |

Red with white band |

|

Ampol |

Blue and white |

|

Caltex |

Light Grey |

|

Total |

Silver |

Smaller drums, 4 and 1 gallon could be more in company colours at the time.

Cunnamulla.

Caltex Oil Pty Ltd – Dead

end siding

B. P. Aust. Ltd – Dead End 1 chain.

On the North Coast Line let’s look at the Gympie area, things were more spread out.

Manley (Sunshine Coast Hinterland)

In 1973/4, Golden Fleece

fuel in 44 gal drums arrived at Landsborough in open “H” wagons. The Manley

Co-ordinate contractor would load the drums onto his truck for the final leg up

the hill to the depot. The station ASM’s would buy a drum from the carrier and

store it in the goods shed. The goods shed had three doors, there was a drum of

Super on each side of all doors.

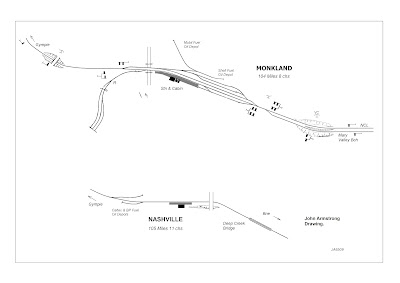

Monkland (south side)

Mobil Oil Coy’s siding.

Shell Coy’s siding

Nashville

BP and Caltex sidings

Gympie (north side)

107 M 35 ch. Golden Fleece Siding.

This diagram by John Armstrong give an overview of the area, two (2) sidings face south and two (2) face north. Some shunting would be required for this crew. There was a local shunt train 4S and 5S in the working timetable to shunt the area. 4S departed Gympie 8:25 am, arrive Monkland 8:55 am. 5S returned Monkland depart 12:05 Pm, arrive Gympie 12:25 PM, wagons were to connect with shunt train 462 departing Gympie at 2:25Pm for Brisbane.

That’s some point work for two sidings??.

A somewhat overgrown Caltex depot in Ingham. Not shown in the siding book, but it gives an overview of a different tank arrangement that could be used on the layout.

Branch lines offer it all as well. Most lines had an axle load of 10 tons, restricting the size of wagons that could be used. Only the smaller wagon were allowed. OB, OC, OP, OT, OV (32 tons gross loaded) OCE, OPE, OTE, OVE (40 tons gross loaded).

Urangan on the Pialba

Branch, (the Harvey Bay area of today) had a coastal oil terminal. Fuel was

shipped into the terminal. Tank wagons were loaded out for country

destinations.

It was a Caltex terminal. Not a big operation, just one wagon at a time. At the time the photos were taken, mid 1970’s fuel was being sent to Kingaroy. That’s three trains, Urangan to Maryborough, Maryborough to Gympie, and Gympie to Kingaroy. Maybe a wagon could do two round trips a week if the wagon was loaded and unloaded on the day of arrival.

The Urangan train

doing roadside work at Scarness

Kingaroy

Branch

Murgon (Proston Branch) -

Esso Oil Coy Pty Ltd Siding (33 ch.) Dead end siding.

Wondai - BP (Aust) Ltd

siding, loop 2 chain long.

Kingaroy – Mobil Oil Co’s

siding

Shell Co.’s Siding.

Caltex (Q’land) Pty Ltd siding off the Fork.

Gayndah

– Monto Branch

Mundubbera - Esso Oil Coy

Pty Ltd Siding.

Monto - Shell Co.’s Siding.

Brisbane

Valley Branch.

Yarraman - Mobil Oil Co’s

siding

Ampol Petroleum

Shell Coy of Aust Pty Ltd

Siding

Golden Fleece

Requirements and what was done changed with time due to changes in regulations, signage, piping, sheds etc.

Some great articles and photo of country depots can be found in Australian Journal of Railway Modelling magazines.

Issue # 7. Golden Fleece

depot truck

Issue # 10 Country Oil Depots

Issue # 11 Modelling an Oil Depot.

Some back issues are still available from Stephen Johnson Models.

Australian Model Railway

Magazine No.309 December 2014.

Beyond the Fence – Country Oil Depots.

Model.

On the layout I have a Shell depot that was scratch built a number of years ago, it’s on the standard gauge network. Again it is not very wide, the drum shed has no siding.

The tanks were made vertical due to space available on the layout.

As a space

filler, farm tanks are being stored.

The tanks are PVC tube and the tops were cut from the bottom of a Coke can.

Tanks for the shunting

layout are PVC tube from the local hardware store and styrene was used for the

tops. At the start I was looking at two different sizes.

Using a photo of the Dalby depot, a plan for the drum shed was drawn up with the assistance of other shed plans found in the Australian Model Railway Magazine.

The shed was going to be

built with the roof fixed into position, aluminium angle was used to line up

the inside posts and make sure they were square.

40 thou styrene rod was used to make up the pipes. Pumps were made from larger size styrene tube and rod. Hatches on the tank sides and top for spare Tichy Train Group drum lids.

After a check of the internet, drums were painted and added to the shed. The 44 gal drums are Tichy Train Group # 8212 HO 55 gal drums (96 drums with lids). The smaller drums came for Walter’s

Lights (4020 LED’s) were

added to the shed to highlight the drums in the shed. No lights were placed on

the tanks, I was thinking it’s a smaller country depot and it would be daylight

work only.

The HJS steel open wagon

was scratch built. Drum load is Tichy Train Group 55 gal drums. At the time of construction, I didn’t have the

required number of drum for a full open load. The section covered with the

tarpaulin was built up using styrene sheet, additional box size strip was

placed on top. Once covered with the tarpaulin it would look as if on top of

the drum was cartoons of oil/grease etc.

To paint the floor and inside the shed once built, a very expensive tool was purchased??. An OO paint brush nearing its expiry date had the ferrule was bent 90° with a pair of pliers.

The ladder to the walk way on top of the tanks is a Tichy Train Group # 8002 Safety Cage Ladder & Stairs kit. It was a bit short one end, thus the second platform. The walkway is styrene and brass rod soldered for the hand rails.

Pipes and stop

cocks handles were all coloured coded

If this size tank wagon is in the depot, it’s not a Branch line location.

Many depots had portable

tanks for round town bulk deliveries. Timber blocks were shaped and a stand

build from styrene strips. These will be added to the depot once in place on the

layout.

Once on the layout, other additional detail will be added around the depot once it is known what space is available. Fencing, gates, depot office all will be considered.

One of the hardest part of operations is identifying what goes where. The depot should make that a little easier. Plus having the two parts to the depot provides additional operational opportunities.

Talking about operations,

back in blog posting December 2019, I showed one of my operations methods. A second

video, train 569 has been as been added to the YouTube channel.

A couple of weeks ago we headed down to Melbourne with the family, a visit to Puffing Billy was a must. Yes, they turn it on for us. I guess something for us Queenslanders ????

Was it cold, you bet, it

was freezing, brass monkey weather at the very best, the wind was blowing,

raining, not the best day to be out and about. We were advised that was even

too cold for the steam engine to get out of bed. The early train was worked with

steam. Riding in a steel floored and sided wagon didn’t help.

My apologies, I acknowledge some of the photos have been used in other blogs posting previously. They are applicable to the project, just trying to keep it all in one house.

Not sure what next month will bring, so much in the pot at present, new rollingstock being released, IDR with the SX cars and SDS/CGL with the BEZY/QQAY container wagons. Other structures are well on the way as well.

Trust you find something useful for your modelling endeavours.

Happy

modelling.

Acknowledgements

AMRA Qld Library.

Queensland State Archives

QR Stations, Stopping Places

and Isolated Siding 3rd January 1963.

John Kerr Notes.

John Armstrong.