It’s been 20 years now since I started building the layout. With both boys married, the table tennis table gone to a new home, I had somewhere to build a layout. With the main focus being modelling the 1960’s there was going to be a fair amount of scratch building. At the time advice given was good, some was going to be trial and error as one tries something different.

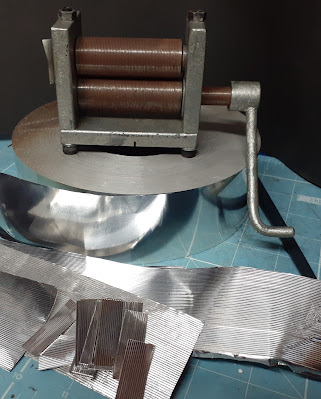

It would not be Queensland without corrugated iron roofing on buildings. At the time where was various methods for adding C.G.I. roofing. A number of manufactures produced grooved aluminium foil that looked the part. And you could also make your own which I did a number of times and still do today. Kerrie brother–in-law worked for an aluminium plant in Sydney and he was able to obtain a roll of foil for me. Later when the club roller went missing, he made one for me from photos. This was great for making single sheets of C.G.I., it was time consuming with good results.

Most of my building were

made from styrene sheet and the aluminium foil sheets were glued to the top for

a roof or siding. At the time, various wise words were given on how to do it, I

picked one and when with it. I used “Contact Cement”, that yellow sticky stuff.

All was good for a period and then the roofs started bowing.

A number of structures

were build this way, some have bowed more than others, resulting a few were in

a need of a reno.

This old station building is now the sawmill office. The roof has started to buckle.

Likewise, this church

roof is twisting. The roof was made detachable for lighting to be added. It’s

OK for now.

The tranships shed roof has also twisted a bit, it has been like that for some time, maybe it adds a bit of realism for an old structure. To fix it, a full rebuild would be required. I now use Supa Glue (CA) to fix the aluminium roofing iron to styrene.

Since joining the NMRA, attending conventions and doing the Achievement Program (AP), it has shown me how to make better models, thus some buildings on the layout now look a bit ordinary. Coupled to this, things do age and that shows. Overall I’m happy with the track plan and the trains run without any issues, the layout provides what I enjoy doing with mix of both continuous running and shunting operations. So, it’s about time I do something to update the layout scenery and give the layout a new lease of life.

The farm shed has been reroofed with Evergreen # 4526 Metal siding styrene sheet. The sheet is .040” thick and the spacing is the same. Lighting was added during the reno. In the past I have not used the styrene sheet due to its thickness. But, when adding fascia’s and barge boards, what thickness, it’s covered up.

I think sometimes we model how things are built, more so that how it looks or how we see it. We all know that corrugated iron roofing is many sheets and the sheets can be various size. The sheets are added across the structure in rows. So that’s the way we model it. Take a look back to the transhipping shed. That may look OK for an old structure where maintenance is lacking. The prototype shed had a few sheets missing, a 59 class steam loco did a wheel slip in the shed and a few sheets went up to the heavens and were never replaced. What about a new roof or a roof that has been well maintained, do you see individual sheets in each row? The sheets are very thin and overlap on the curve making then all most impossible to see, you can see where the sheets overlap for the various rows going up the roof to full enclose the structure from the weather. This house roof is styrene sheet, individual sheets were scribed into the sheet using the back of a # 11 cutting blade. It looks good, but is it over kill?

Of late when using the

styrene sheet and scoring lines I show the rows only.

Woodhill Community Hall.

Given the age of the hall, individual sheets are showing. I think this can be captured in the weathering.

When I built the hall I made the roof

detachable so lighting could be added later, you know, one of them down the

track projects, it was not a very good job. Given the poor construction method

I used, it didn’t take much time for the roof to fall apart. After some time (a

few, many years) the roof was replaced and lighting added.

The LED’s are 0402

prewired purchased from EBay. The leads have very thin enamel wire and in some

locations the wire is inserted into styrene tube. LED’s shine outwards and

don’t emit light like an incandescent light bulb. You may not be happy with the

results hanging them from the ceiling like your house. I sit the LED in the

corner of the room facing outwards towards the windows. As the hall was already

constructed, port holes were made and the LEDs were position in them to shine

outwards or towards the subject you are highlighting.

Talking of lights, one think missing on the layout was street and yard lights. There are one or two in selected locations and a couple of building with lights. Adding lights would add another dimension to the layout. Given the 1960’s era I model, not a lot of choices are available to me, lots to pick from for earlier and later eras on EBay. Adding lighting would enhance the layout and give it a new lease of life.

During that era, street and yard lighting were not that flash, I recall platform lights we were allow 40 W incandescent bulbs. It was a full time job keeping them, the youth of the day took pleasure in removing them when the station was unattended. That was until we place graphite grease at the top of the pole. Some even came to the office asking how to remove the grease. Boy, didn’t we have fun with them.

At night yard lights were used as detector for shunt moves from the signal cabin, as a string of wagons moved down the yard, and the light shining on the last wagon gave clearance of points. Station Masters had guidelines in the “Station Instruction Book” on the use of lights. The cabin light (generally just one 40 W incandescent light bulb hanging from the ceiling) was to be on only when working the cabin. I recall one station the office and parcel area was longer than most stations, it had 3 x 40 W incandescent light bulb hanging from the ceiling for the whole area, the instruction was maximum of two lights were to be on at any one time. Station Masters at night would sit on their front verandas to ensure the instructions were followed. All I can say, so of them old buggers didn’t sleep much at night.

The back pages of Working Time Tables contained instructions for Guards working passenger trains regarding the turning on and off of platform lights at unattended stations for their train. After we were married in 1972 and I was returned to the Northern Division for my next job, we stopped at one station north of Bowen where I had been working to show Kerrie the Station Masters ringer washing machine, to do the washing it was kicked started like a motor bike, there was no power in the area. The world has come a long way in fifty years.

The same station is where I recorded (notice I recorded, not head office) my second derailment, I was pushing (yes me, the shunt engine) an empty FJS (4 wheeled) wagon around the leg of the angle when the wagon dropped into the dirt. The wagon was on the northern leg of the angle and was to be picked up by a south bound train, I decided to push the wagon to the angle apex to make the pickup/attach an easy shunt for the crew. The Ganger and myself using rail jacks was able to place the wagon back on the tracks.

Back to the layout, I decided two different types of lights would be required. A goose neck type for platforms, and pole mounted lights for street and yard lights. During the 1960’s QR used or replace timber poles with 40 lb worn rail. For street lights, I need timber poles and for the yard lights I need a mix of timber and rail poles. The plan was to use warm white 0402 SMD LEDs with pre-soldered enamel (magnet) wire, 0.1 mm dia. The last pack was purchase on-line from Kogan.com, 20 lights for $ 14.00. Tichy Train Group # 8027 Lamp Reflectors (24) were purchased from Gwydir Valley Models for $7.00 per pack. The lamp brackets were made from K & S #9830 (1mm x .225mm) thin wall brass tube picked up from Hobby One for around $10.00. For the posts I used code 40 rail from Gwydir Valley Models and for the wooden poles Evergreen # 224 ⅛” (3.2mm) styrene tube.

Platform

Lights.

To start the inside of the lamp shade/reflector was painted white. After the paint was dry, a 0.5 mm drill was used to clean out the paint. A length of 1 mm brass tube was cut to length, allow for some to go through the base board, best to have some extra than to be to short. The LED leads were thread through the lamp shade and down the tube. Once happy with the position of the light shade, I add a small drop of Super Glue to keep it all together. On some, before threading the leads down the tube I put a 90° bend in the wire at the LED to position the front of the LED outwards in the shade. The LED was secured in the jaws of a pair of tweezers to bend the wire. I didn’t have any issues using the tweezers, I have read that static electricity in steel tools can damage the LED, they suggest grounding tools before using them. I see special tools in Jaycar Electronics that are ESD safe. Maybe, they could also be useful when adding styrene detail as well. Small parts sticking to the tweezers, it that static electricity ???

Using the Kadee plies, a

loop was form in the end of the brass tube. This light was being used for a

bill board, the end was bent over centre.

The brass tube was glued to the rear of the bill board along the centre upright timber. The LED’s come with a 1 K resister, I generally add a 1.8 K or 2.2 K resistor in lieu.

Wooden Light Poles.

For the wooden poles I use Luke Towan method from one of his tutorials (May 2019). My poles are smaller to reflect their application as just being light poles. My poles are 95 mm high, some of this drops down into the base board.

To give a timber look, a cutting blade was run along the tube to take the roundness look off the tube as if bark had been removed.

Once again I used the K & S 1mm brass tube for the light

bracket and useing a similar method of construction as to the platform lights.

The LED wires run down in the centre of the tube to under the base board.

Being just over 3 mm in diameter, the resister could be added on the workbench instead looking upwards under the layout.

Rail type Poles.

Insulators are

the same as the timber poles. 0.3 mm brass rod was used for bracing.

A jig was made to

keep everything square and uniform.

Some poles may need additional cross bars to change the direction of wire to other poles.

Rail type poles

were added to rail yards

Wooden poles

were added to streets and local industries.

Overall, 50

lights were added to the layout

Reduced overhead room lighting helps to capture the night scene, yard lights highlight sections of the layout.

Late loading of

sheep under light.

The tranship

shed is a 24/7 operation, lights helps to highlight activity in the shed.

KKB Cattle Drover/Guards van waits to be loaded.

Westgate western end of the yard.

Army camp with lights.

The next two photos captures a different angle of the Westgate engine shed. A reverse view from the back scene to the centre

This is the centre passage way view that is normally viewed by operators.

Lights were added to the gantry crane using the brass goose necks made for the pole lights.

The standard

gauge Shell fuel depot had security lights added along the railway fence.

I guess, the depot was a day time operation only.

Westgate East level crossing as DEL 2400 works a train out of town.

The street

light helps the guy mow his yard in the cold of the evening ???

A few lights

were added to the transhipping road.

A general

evening view of the eastern end of Westgate yard.

As I was added the lights, brightness was tossed around a lot. The lights were added to bring life to the layout. Do you only see them with the room lights off? Would be hard to operation in complete darkness. Or do you have them so they are visible with the room lights on and at what level of brightness.

Wyandra station

was fitted with lights when built a few years back. Maybe they are too bright

and need turning down a little.

The saw mill had lights

fitted during construction some time back.

A goose neck light pole was used for the rail ambulance shed.

When adding the scenery to the layout during construction, the grass was homemade, sawdust from cutting up the frame was coloured using clothing dye. Over time the colour has dropped out and parts of the layout was starting to look shabby. Plus, there was far too much dirt. So during the month static grass was added to vary parts to the western end of the layout.

Grass was added to areas between the various roads.

Grass was added to the out perimeters of the cattle and sheep yards.

The local cricket ground had a full makeover, various shades of grass were used and finished off blending it altogether with the air brush.

A cricket pitch was added to the joy of locals.

Some grass was added to the standard gauge loco stabling road.

A few small area of land on the eastern end of Wyandra had some greener grass added with some flowering weeds. Station Master “Bill” with his green flag is waiting for the shunt to arrive, a crossing with a passenger train is come up and the Rule Book regulations requires the shunt train to be in the loop. No fixed signal for admitting trains to the loop, just a home signal for the main line.

Trust you found the information helpful and is of assistance to you in your modelling endeavours.

Your comments on the brightness of the lights would be very much appreciated.

Stay safe and enjoy your modelling until next time.

Arthur H.

No comments:

Post a Comment